Bernard Pyron Stoneware Potter

I took courses in pottery under Harvey Littleton and Tom McLaughlin, who was a teaching assistant then.

I remember several of the pottery students of Harvey Littleton,

especially Clayton Bailey, Monona Rossol, Tom McLaughlin, Tom Malone,

Gloria Welniak, and Carlon Welton.

I took courses in pottery under Harvey Littleton and Tom McLaughlin, who was a teaching assistant then.

I remember several of the pottery students of Harvey Littleton,

especially Clayton Bailey, Monona Rossol, Tom McLaughlin, Tom Malone,

Gloria Welniak, and Carlon Welton.I was a graduate student in experimental psychology, with a Ph.D. minor in art history, mostly the art history of Frank Lloyd Wright under John Kienitz. But I had an interest in pottery going back many years when I dug up grey clay from a nearby ditch and made pots out of it, which I tried to fire in my mother's oven. I started in pottery at the Madison, Wisconsin Vocational School in the late fifties, and the next year I took pottery in the art department of the University.

Clayton Bailey, myself, Monona Rossol, occasionally Gloria Welniak and Carlon Welton, with some other art majors, were part of a group who met regularly to make improvised music based on medieval, far eastern and American folk music with a music major, Dennis Murphy, as our leader. Bailey and I were not musicians at all but Dennis taught us to play mouth bows which we made. Bailey still makes them.

Later in the mid sixties,Bailey and I taught at Whitewater State University, where I had an joint appointment in art and education.

I remember one time when Tom McLaughlin got married to a women whose name I have forgotten, but she was also a pottery student under Littleton. The Littletons were away and let the newly wed couple stay at their house out in the country southwest of Madison. Bailey and I with our wives parked on the road near the Littleton driveway and Bailey and I slipped up to the house and suddenly appeared under the kitchen window.

Bailey

in the spring and summer of 1962 lived in a rented place out in that

same area , but not as far as Littleton's, where we had a music session

around a large campfire with horns blowing, Murphy playing his sitar,

Monona wailing or singing, some pounding on the drums etc.

I learned to build down draft gas fired stoneware pottery kilns when the larger kiln was built in about 1961 in the University of Wisconsin pottery shop under the Education Building. I built one in Crestwood of Madison and another in Whitewater, Wisconsin. Bailey built a smaller salt glazing kiln beside it.

I learned to build down draft gas fired stoneware pottery kilns when the larger kiln was built in about 1961 in the University of Wisconsin pottery shop under the Education Building. I built one in Crestwood of Madison and another in Whitewater, Wisconsin. Bailey built a smaller salt glazing kiln beside it.

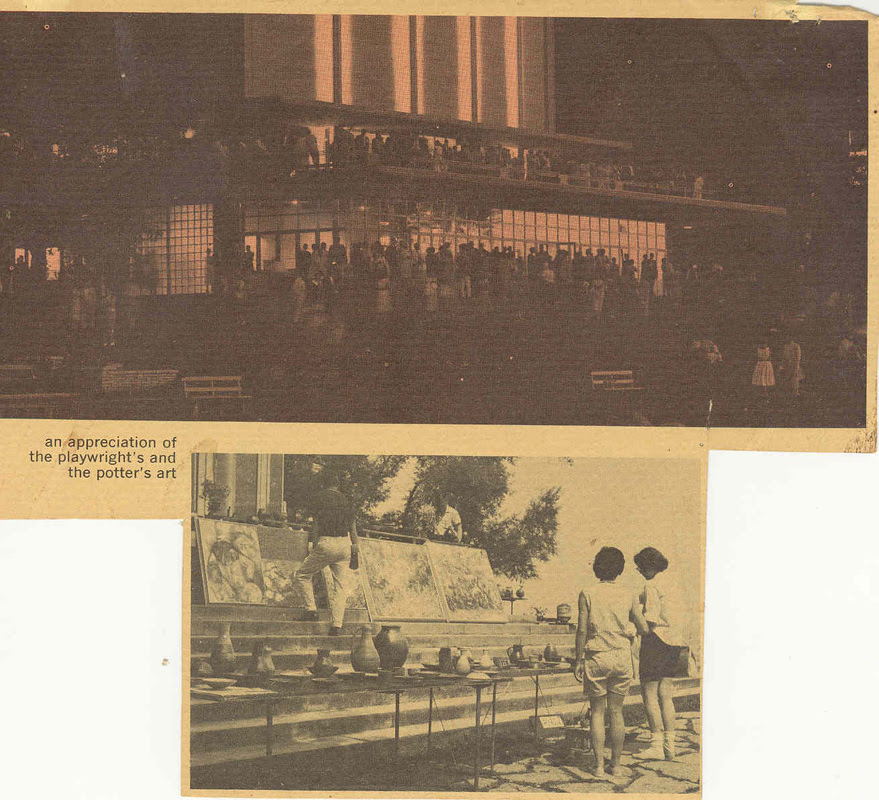

Several of my pots of 1962

In

1961 to 1962 I took many of my pots to the University of Wisconsin Mall

in front of the main library to sell, and once, shown above, I had my

pots at the lake side of the Student Union Auditorium.

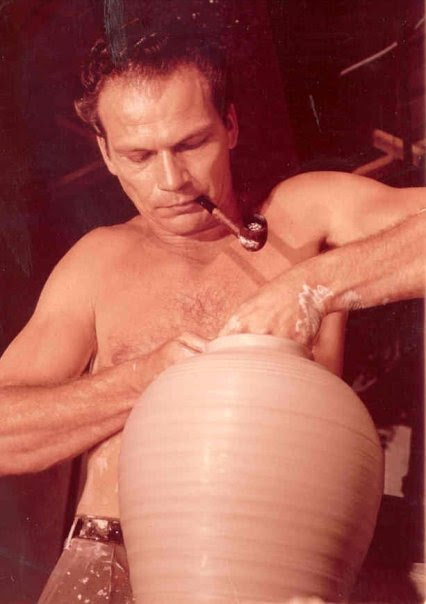

Above,

Me Throwing a Vase In 1962 In My Pottery Studio in the Basement of Our

House At 5710 Bittersweet Place In Madison, Wisconsin.

Four

of My Celadon Bowls, With Iron Oxide Brushwork. Three of these were in

the Midwest Designer-Craftsman Show of 1962 and were also in the

Smithsonian Travelling Exhibition that year.

A Celadon Bowl With Iron Oxide Brushwork of 1962.

This

Is One of My Plates of 1962 Made In the Studio Basement at 5710

Bittersweet Place. I had a downdraft propane gas fired kiln in the

backyard at 5720 Bittersweet Place, that I fired up to a little above

2300 F, or to about cone 10. I built it myself, The brushwork on the plate is wax resist, which shows a darker layer of glaze underneath.

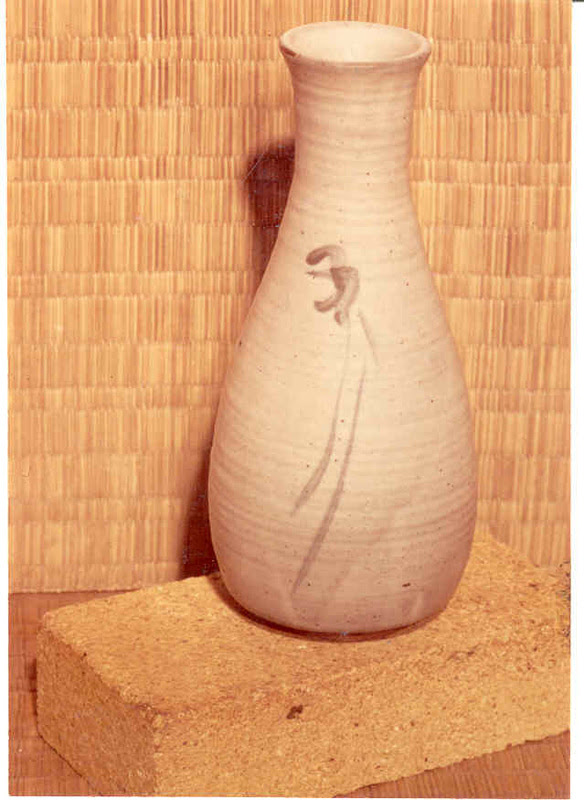

A Stoneware Vase of 1961.

Large Outdoor Lantern of 1962, all wheel-thrown.

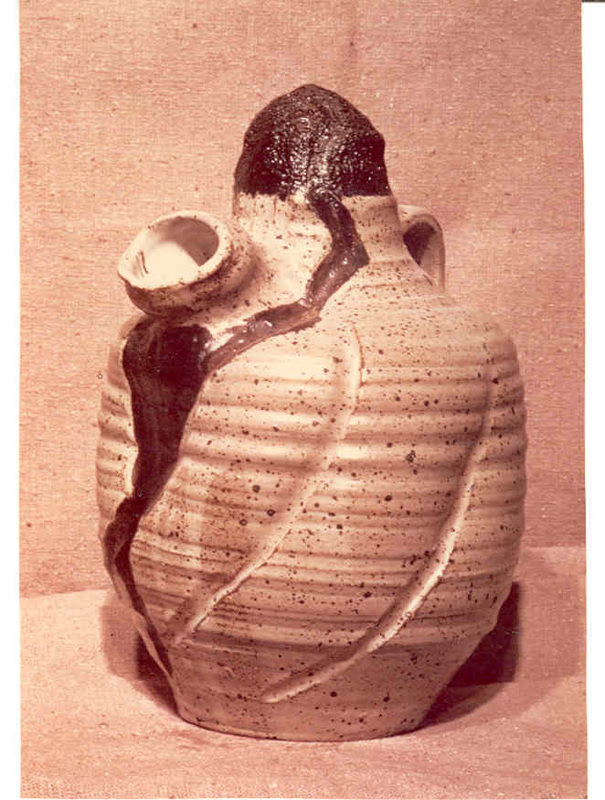

Stoneware Jug of 1962, with the top glaze over-fired.

Unglazed Vase of late 1962 after I moved out of 5710 Bittersweet Place.

Above is my Stoneware Downdraft Pottery Kiln At Whitewater, Wisconsin

Here

Is A Ceramic Piece Thrown On My Pottery Wheel In My Studio Above the

Garage At Whitewater and Fired In my Whitewater Kiln Outside the Garage.

Clayton

Bailey Built This Smaller Kiln To Be Used For Salt Firing. It was to

the west beside my larger stoneware kiln. Bailey simplified

the process of building a kiln by using a mix of grog, fireclay and insulating material mixed up with water which he poured in between the firebrick walls of the interior and the forms, which were old tables or boards. The top was a large kiln shelf. When the kiln was fired the insulating material hardened to become like insulating brick. Not using insulating bricks cut down on the cost of the kiln considerably. Note the square opening six inches or so above the bottom. Thats for the propane gas pipe. Bailey put a row of firebricks in front of the gas pipe to form a down draft kiln. The back had to be bricked up each time the kiln was fired. It worked.

the process of building a kiln by using a mix of grog, fireclay and insulating material mixed up with water which he poured in between the firebrick walls of the interior and the forms, which were old tables or boards. The top was a large kiln shelf. When the kiln was fired the insulating material hardened to become like insulating brick. Not using insulating bricks cut down on the cost of the kiln considerably. Note the square opening six inches or so above the bottom. Thats for the propane gas pipe. Bailey put a row of firebricks in front of the gas pipe to form a down draft kiln. The back had to be bricked up each time the kiln was fired. It worked.

The

inexpensive quickly built salt glazing kiln is here ready to fire. See

the slot opening in the side of the kiln? Thats for shoving in small

paper cups of wet salt into the kiln when it reaches about 2300 degrees

F. We often fired the salt kiln, and later the larger kiln was used as

a salt glazing kiln, at night. When the cups of wet salt, often mixed

with copper, or something else for color, were shoved into the white hot

kiln, there would be a small explosion and clouds of white gas would

come billowing out of the blow hole, which you can see at the bottom of

the bricked up back wall.

On the table above, with some smaller ceramic pieces, leaves and apples, are two of my Whitewater Salt Glazed wheel-thrown pieces.

Those are four Frank Lloyd Wright designed chairs from the Ward

Willitts house around the table. Thats Patos, my dog, under the table.User Comments

| I LOVE pottery! An excellent blog! When I lived in north GA, the Meaders were notorious for their pottery...I love the face jugs...thank you for sharing. :) |

| thank you so much for showing me your websight it was facinating and I learned a lot about your past and what an artist you are thanks again Becky at F.oods for Health. |

Email

Email Print Article

Print Article Favorites

Favorites Report Abuse

Report Abuse